tensile testing machine components|tensile strength tester machine manufacturer : purchasers For a given material or component, a tensile testing machine can test its mechanical properties by a variety of methods, each test method or test type will reveal different behaviors and characteristics. The following will describe the 6 main test types of the tensile testing machine, which can help you indicate which test type is required for .

webCARTA 1 – O CAVALEIRO. A imagem é de um Cavaleiro destemido, ousado, corajoso e determinado. Ele está vestido com uniforme de guerreiro (o que mostra que veio para .

{plog:ftitle_list}

Ana Akiva, ex-pastora evangélica e musa do OnlyFans que d.

A Universal testing machine (UTM) is used to test the mechanical properties (tension, compression etc.) of a given test specimen by exerting tensile, .

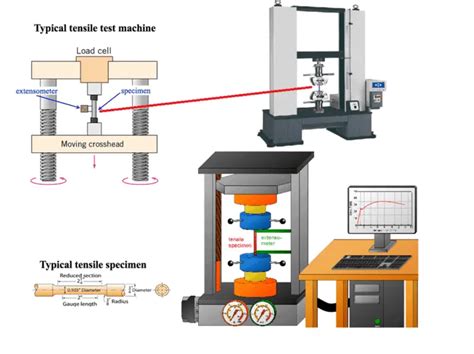

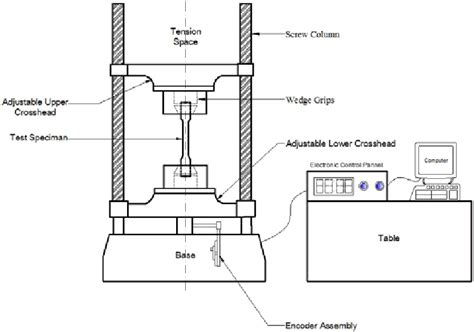

Tensile or universal testing machines (UTM's) are used to determine physical (mechanical) material properties and to perform material/component testing. The two main parameters are force and length, as a change of dimension . To conduct a tensile test, specific equipment is required, including a tensile testing machine, grips, extensometers, and a data acquisition system. The machine applies the force to the sample and measures the force and elongation. . Essential components include a well-calibrated tensile testing machine, secure grips to firmly hold the sample .Our universal testing machines for static applications are specially designed for tensile tests, compression tests, flexure tests and shear tests. They are ideal for standard tests, but also for complex test tasks in the field of materials and .Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum .

For a given material or component, a tensile testing machine can test its mechanical properties by a variety of methods, each test method or test type will reveal different behaviors and characteristics. The following will describe the 6 main test types of the tensile testing machine, which can help you indicate which test type is required for .Our materials testing machines are used in R&D and for quality assurance in more than 20 industries. . For this reason we develop and manufacture both the load frames and all main components ourselves. Whether tensile test, compression test or flexure tests, function tests or standard tests, texture analysis or fatigue testing: with our .

Discover the critical role of tensile testing machines in material testing, exploring types, functions, and standards like ASTM D638 and ISO 527-2. Learn how Pacorr's equipment leads the industry. . to components used in various industries can be tested for tensile strength. Q: How does compliance with ASTM D638 and ISO 527-2 impact my . From aerospace components to automotive parts, from construction materials to medical implants, understanding the strength of materials is crucial for ensuring their safety and durability. . Tensile testing machines are used in a wide range of industries and applications. For example, in the aerospace industry, tensile testing machines are .

The tensile testing machine inspekt solo is designed for test loads up to 2.5 kN and is thus mainly used for standard-compliant materials testing and component testing in the small load range. In the load range between 5 kN and 30 kN the tensile testing machines inspekt duo (up to 10 kN) and inspekt blue (20 and 30 kN) convince among others by .

Mecmesin grips and fixtures are integral components of our test systems. Mecmesin has a comprehensive range of grips and fixtures to meet your tensile testing application and budget. . Mecmesin tensile testing machines offer varying grades of sophistication at an affordable price to ensure you: Optimise your designs; Ensure consistency . Key Components of Tensile Test Machines. 1 Load Frames and Actuators The load frame and actuator are critical components of tensile test machines. We’ll delve into the types of load frames .A tensile testing machine is used to perform testing in accordance with several common ISO, ASTM and automotive standards, e.g. ISO 527, ASTM D412, ASTM F88, ASTM A370 and a diversity of other methods. . components and structures to determine how a material reacts to the applied force. Limitations. Width of specimen due to dual column set-up .

Video 1: Tensile testing of annealed Cu sample (video and evolving nominal stress-strain plot) This page titled 5.5: Tensile Testing - Practical Basics is shared under a CC BY-NC-SA license and was authored, remixed, and/or curated by Dissemination of IT for the Promotion of Materials Science (DoITPoMS) via source content that was edited to the .The tensile test is the most important and most frequently used mechanical-technological test worldwide, used to determine the strength and strain characteristic values for metals applications that are of crucial importance in the design and construction of components, commodities, machines, vehicles and buildings.. The test task is to determine material characteristic values .Microdyno Tensile is the series of universal machines for tensile, compression, bending and peeling tests, developed for granting top-tier performances when testing all those materials requiring low loads (that is to say, up to 500 N).The .ProLine is available with test speeds from 0.0005 to 1500 mm/min, depending on type. Testing machine speed is independent of the test load. The high test-speed range can be used without restriction. In addition, test loads up to 110% .

A Universal Testing Machine (UTM), also known as a tensile testing machine/tester, is an electromechanical testing system that applies a tensile force to raw materials or components to test for both tensile and compressive strength. It is widely used for both small and large load testing in quality control or research projects, etc.Our compact bench-top universal testing machines (UTMs), available in 0.5 kN, 1 kN, and 2.5 kN single-column models, are ideal for tensile and compression testing of various materials, products, and components. Powered by the intuitive VectorPro™ software, these portable UTMs (weighing under 30kg) offer powerful performance in minimal bench space. The 2.5 kN model .The tensile test is a test method within mechanical materials testing, used for the determination of material characteristics.Depending on the material, the test is used in accordance with the respective industry standard for determination of the yield strength, tensile strength, strain at break and other material properties.. In the tensile test a material specimen is strained until it .Components testing; Test rig with portal frames for oversized and multi-axial components testing up to 250 kN; Linear motor testing machines up to 10 kN; Wide range of accessories: Our portfolio includes testing with optical extensometers (videoXtens, laserXtens), testing in temperature chambers, and testing with strain gauge applications.

In fact, the equipment used is often termed a universal testing machine (UTM), being capable of a variety of test types that the organization may need to perform. The components required to perform a test procedure are: fixturing to hold the test specimen, a test frame and loadcell capable of applying the desired load,The unit comes equipment with 4 main components: Electronic unit, the loading module (pick-up bracket), the test stand, and the interchangeable measuring unit for methods of Shore, IRHD and VLRH. . Most tensile strength testing machines provide equipment that allow for Young's modulus testing. What is tensile strength?

Materials testing machines with torsion drive enable fast, precise biaxial testing (tensile or compression combined with torsion) of materials or components up to 10,000 Nm. In addition to tests on artificial ball-and-socket joints and bone-replacement material, torsion tests are also performed on items such as clutch plates, steering shafts .Tensile Testing Machine for static or dynamic standard tests > 10 000 kN . en english. . Component testing; Design Size: Static test force: 10000 kN; Accuracy: Class 0.5 according to DIN EN ISO 7500-1; Configuration: Horizontal test frame ZM 10000 with up to .These components allow a tensile testing machine to perform its essential function: to apply a controlled tensile force to a material, measure the material’s response, and provide data on its mechanical properties. The procedures performed to use the Tensile Testing Machine. Performance of a tensile test consists of three main distinct parts: a. Specimen preparation. b. Test setup and equipment. c. Test. All three parts of the tensile test are standardized. The standards for tensile testing are different depending on the type of material being tested, as well as factors such as size and temperature.

The tensile Testing method measures the force required to break a metallic, composite, or plastic specimen and the extent to which the specimen stretches or elongates to that breaking point. Tensile Test Procedure. A tensile specimen of standard dimensions machined from the metal is inserted in a tensile testing machine (shown in the below figure).

typical tensile test machine

photo refractometer

18 de abr. de 2023 · ) Service Active Sp.z.o.o, Intel Academy Name Service Active Sp.z.o.o, Intel Academy Issued By Autorité des marchés financiers (AMF) Date April .

tensile testing machine components|tensile strength tester machine manufacturer